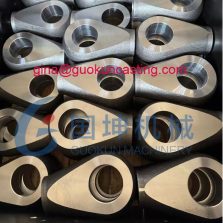

Drop forged hydraulic cylinder yoke

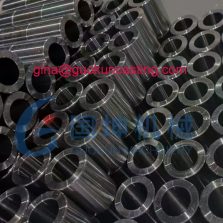

Drop forging, also called closed die forging is a metal shaping process where a heated metal billet is placed between dies and struck by a hammer or press to form the desired shape. It is commonly used for high-strength components like hydraulic cylinder yokes, connecting rods, gears.

The hydraulic cylinder yoke is a critical component that connects the cylinder to other heavy-duty machinery, such as construction equipment, excavators, loaders, cranes, agricultural machinery, tractors, harvester, mining & industrial hydraulic lifting equipment.

If you need customized hydraulic cylinder yokes, please feel free to contact gina@guokuncasting.com to get the quotation.