Super duplex 1.4469 butterfly valve disc

Part name: Stainless steel butterfly valve disc

Metal: Stainless steel CF8, CF8M, 304, 316

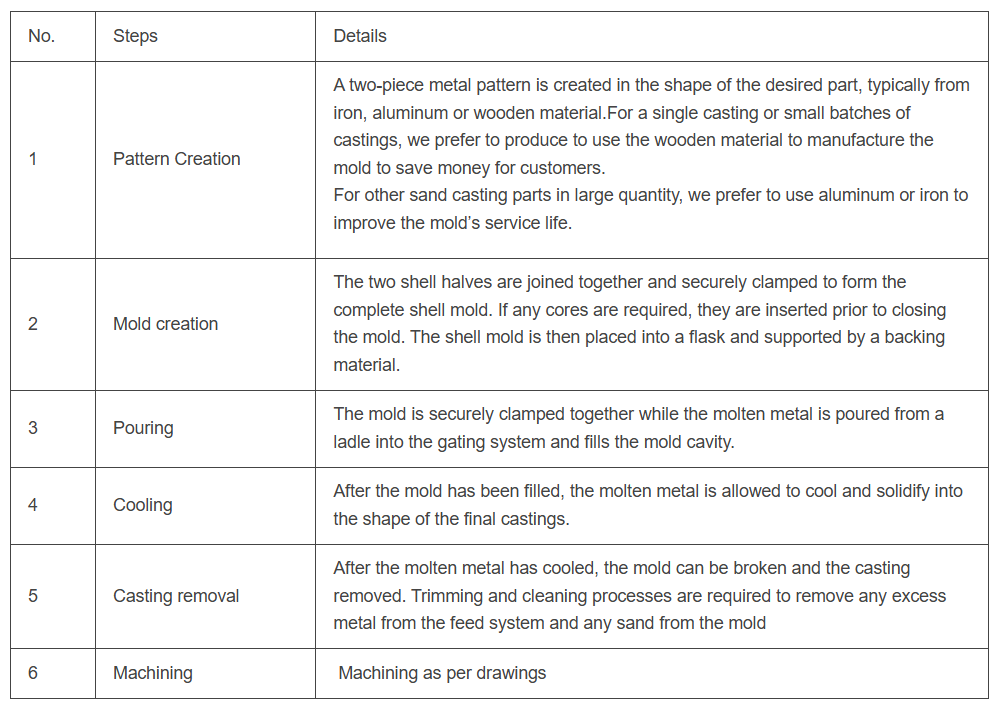

Process: Sand casting for large size valve disc. For small size, we will use investment casting process to cast them.

Baoding Guokun has been specialized in the designing and manufacturing of various valve components for ball valve, gate valve, globe valve, butterfly valve, through conduit gate valve, knife gate valve, bellow valve, strainers and flow control components. If you need investment casting stainless steel butterfly valve disc, please feel free to contact gina@guokuncasting.com to get the quotation or call us 86-18132789710(WhatsApp & WeChat)