CW602N or CuZn36Pb2As Brass

CW602N or CuZn36Pb2As brass is essentially a leaded arsenical brass with a duplex structure. This lead brass is famous for high hardness, moderate strength, corrosion resistance, easy processing, and self-lubricating properties. It is mainly used in the mechanical, automotive, electrial industries, water fittings, valves, pumps and other engineering applications.

| Characteristics | |

| Hardness and strength | With high hardness and moderate strength, it is suitable for various applications that require wear resistance. |

| Corrosion resistance | The addition of arsenic can improve the corrosion resistance of alloys, especially in some acidic environments. |

| Machinable | The high lead content significantly improves the processing performance of the alloy, making it suitable for mechanical processing. |

| Self lubrication | The presence of lead provides excellent self-lubricating properties, reducing friction and wear. |

CW602N, CuZn36Pb2As or CZ132, is a brass alloy with the following chemical composition:

Copper: 61-63%

Zinc:35-37%

Lead: 1.7-2.8%

Arsenic: 0.08-0.15%

Tin: 0.2% Max.

Iron: 0.2% Max.

Aluminum: 0.05% Max.

Manganese: 0.1% Max.

Nickel: 0.3% Max.

Other impurities: 0.5% Max.

Baoding Guokun can supply you different bronze bushes, bushings in various sizes, standard and custom bronze bushings, bronze bushing, flanged bronze bushing, flanged cast bronze bushing, China bronze bushing, bronze liner, bronze slide, bronze nut, bronze worm gear, tin bronze bushing, bronze split bearing, straight bronze bushing, flanged bushings, flanged bronze bushing, oil groove bronze bushing, eccentric bronze bushing, eccentric bronze sleeve, graphite bronze bushing, tapered bronze bushings, single cylinder hydraulic cone crusher series bronze parts, bronze nut, bronze wind wheel, bronze worm gear, bronze slide plate and other related bronze bushing products to our worldwide customers, such as UK, USA, Germany, Australia, Cananda, UAE, Russia, etc.

China centrifugal casting bronze bushing factory

What is centrifugal casting process?

Centrifugal casting is a metal casting process where molten metal is poured into a rapidly rotating mold, causing centrifugal force to distribute the metal evenly against the mold’s inner surface, resulting in a dense, defect-free casting products, typically used to produce axi-symmetric parts with consistent all thickness, like cylinder, bushing, rings, pipes, which will be widely used for aerospace, marine, power transmission, cone crusher, mining and other industrial applications.

The several steps of centrifugal casting techniques:

| Centrifugal casting process | ||

| 1 | Prepare the mold | After producing the metal mold, we need clean the mold’s inner surface to remove debris and contaminants. Apply a cermaic slurry to the inner surface to protect the mold and help remove the casting later. |

| 2 | Pour the metal | After heating the metal and spining the mold, we need pour the molten metal into the rotating mold. |

| 3 | Cool the metal | Use the rotational motion to help the metal cool and create pressure within the mold. |

| 4 | Remove the castings | Stop the rotation and remove the solidifed casting from the mold |

| 5 | Post-processing | Sand blasting and CNC machining |

Advantages of centrifugal casting process

Enhanced material quality: Centrifugal forces push impurities and gas out of the mold, resulting in a uniform grain structure and eliminating porosity.

Faster production times: Castings are closer to their final shape, so no less machining time than forging process, sand casting process and investment casting parts.

Large bronze bushings: Baoding Guokun can use centrifugal casting process to produce large bronze bushings with diameter from 40mm to 2000mm, weight from 0.1 kg to 5000 kgs.

Disadvantages of centrifugal casting method

Limited to cylindrical shapes: Centrifugal casting is primarily suitable for cylindrical casting products.

Not suitable for alloys with gravity separation: Centrifugal casting is not suitable for alloys that are prone to gravity separation, such as lead-bronze.

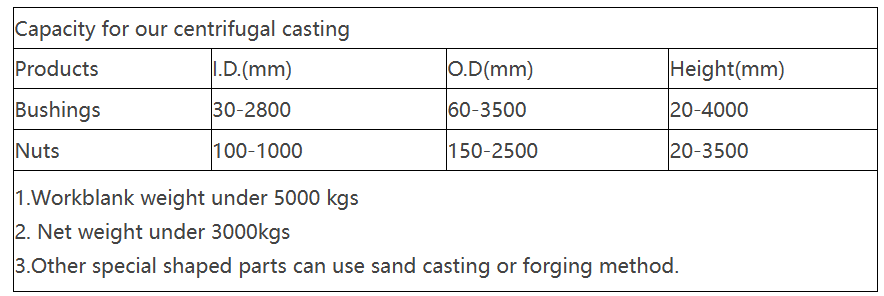

Baoding Guokun Centrifugal casting capacity

Metal information of brass, copper and bronze casting products

Aluminum Bronze Casting Alloys: C95200, C95300, C95400, C95500, C95800

Aluminum bronze alloys generally contain 9-12% aluminum and up to 6% iron and nickel. These alloys have superior corrosion resistance, high strength, toughness, and wear resistance. Alloys with over 10% aluminum content can be heat treated for superior tensile strength.

The normal nickel aluminum bronze alloy we use is ASTM B148 UNS C95800 or 9-4-4-2, famous for its corrosion resistance, especially for salt water corrosion.

A High Quality China Foundry!

Guokun Casting, of Baoding Hebei is an ISO 9001-2008 registered iron and steel foundry & supplier of high quality carbon steel, cast iron and machined castings used in power, mining, railway, agricultural, tillage, truck, automobile, pump, valve, motor, pipe fittings and gear industry.

With a monthly capacity of 10,000kgs and with more than 25 years of experience ensure the short delivery and the highest valued iron & steel casting parts.

Pump casting, Valve casting, agricultural casting, aircraft casting, railway casting, road casting, motor casting, mining casting, power generation investment casting, Medical casting, marine industry casting

Baoding Guokun Machinery Co., Ltd.

Baoding Guokun Export and Import Trading Co., Ltd

Office Add: 777# Chaoyang South Street, Baoding City, Hebei, 071000, China

Factory Address: Wangdu County, Baoding City, Hebei, 071000, China

Website: www.metalcastingfactory.com

Tel: 86-312-5951319 Fax: 86-312-5951296

Phone: 86-181 3278 9710 (WhatsApp & WeChat)

Email: gina@guokuncasting.com