Explosion-proof light housing

Part name: Explosion-proof light housing

Metal: Stainless steel 316 or CF8M

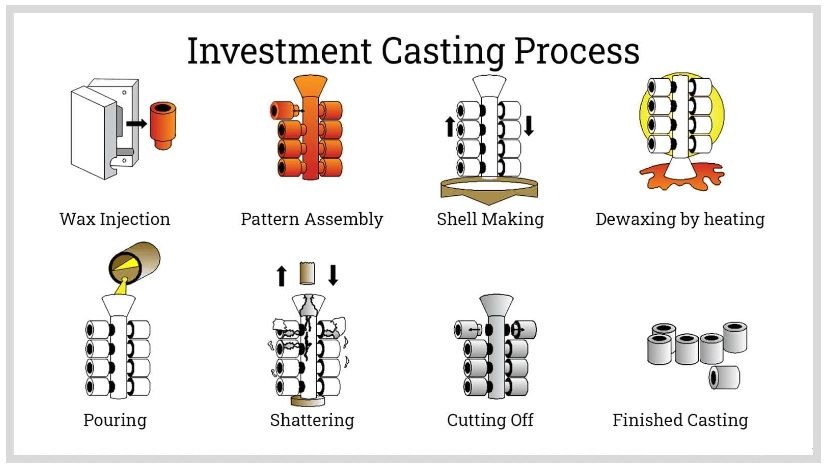

Metal casting process: silica sol investment casting for light housing

Baoding Guokun, with 25 years casting experience, can produce various stainless steel investment casting for various industries. Lost wax investment casting process can produce complex parts that are near-net shape. The stainless steel lost-wax casting parts manufactured by Baoding Guokun is with complex shapes, tight and accurate tolerances that have a standard of +/-0.005, fine surface finish 125 μin (3.2 μm Ra), minimal machining to reduce time and cost and cost-effective. Please mail your inquiry to gina@guokuncasting.com