Electric motor end shield

Part name: electric motor bearing end shield, front end shield, rear end shield, motor housing hub end cover, motor end caps

Metal: cast gray iron motor bearing covers ASTM A48 Class 20, calss 35

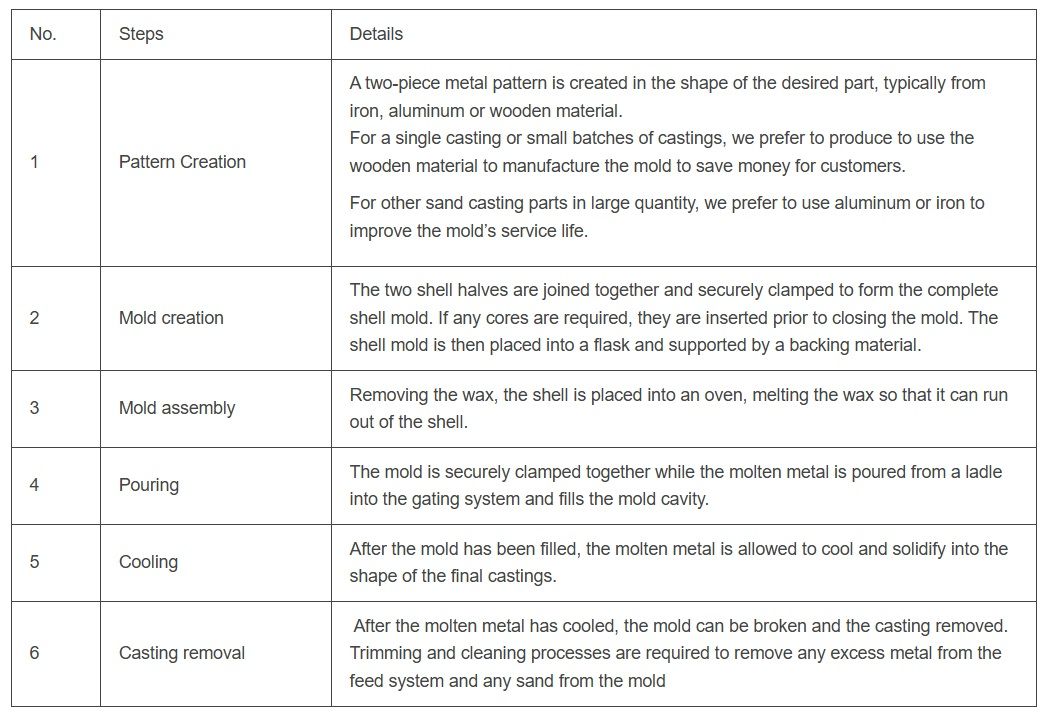

Process: Sand molding casting process

Weight controlled: 1-500 kgs

Surface treatment: Anti-rust oil or painting

Baoding Guokun can produce various electrical motor bearing covers in grey iron, ductile iron, cast iron as per your drawings. ASTM A48, ASTM A536 is normal cast iron used for motor castings. If similar need, please contact gina@guokuncasting.com to get a quotation.