Ductile iron trailer wheel hub manufacturer

Part name: truck trailer axles wheel hub

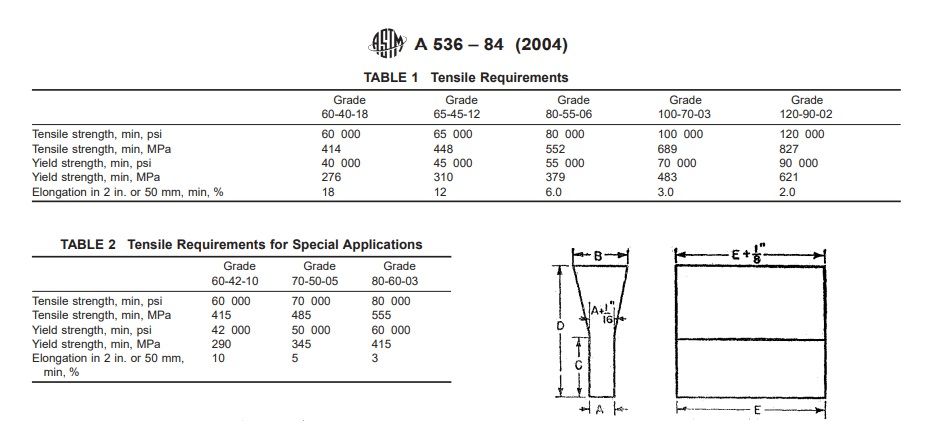

Metal: cast iron, ductile iron QT450 or cast steel

Wheel Hub diameter: 16~20 inch

HS code: 87087050

Process: Sand Molding Casting process

Application: heavy truck trailer, semi-trailer, tractor

Baoding Guokun is a China metal casting factory and exporter that is concerned with the design, development and production of truck and semi-trailer brake parts, such as brake drum, wheel hub, brake shoe, brake pad and brake disc as per customer’s drawings or requirements. Please mail your inquiry to gina@guokuncasting.com to get the quotation.