China shell mold casting factory

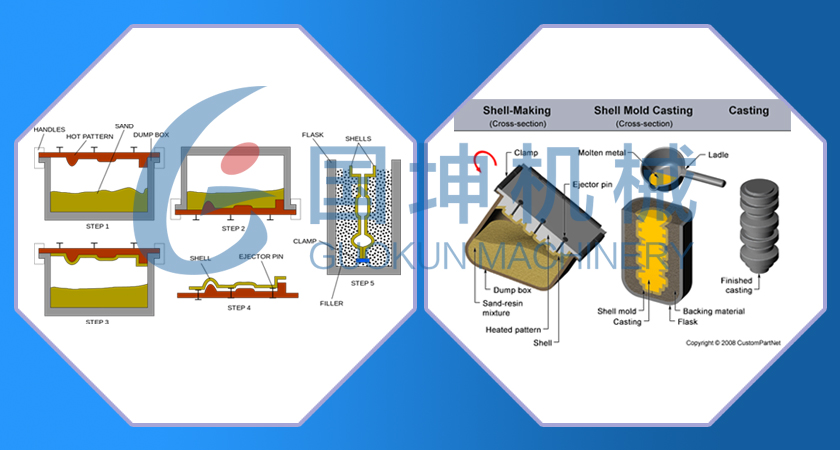

Shell Mould Casting is an expendable mold casting process that uses a resin covered sand to form the mold. As compared to sand casting, this process has better dimensional accuracy, a higher productivity rate, and lower labor requirements. It is used for small to medium parts that require high precision. Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. However, in shell mold casting, the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired parts, is reused to form multiple shell molds.