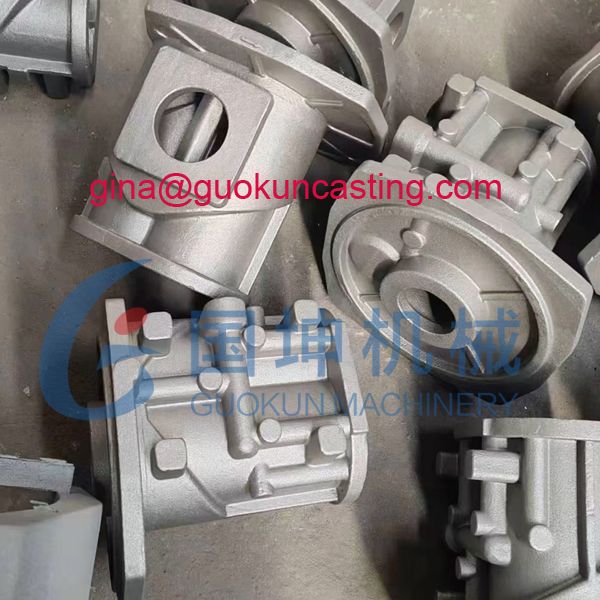

Cast iron Lost foam casting Screw Compressor housing

Baoding Guokun is engaged in manufacturing and supplying quality range of Compressor housings for many years. These are manufactured from quality tested components and are in high demand by our clients spread worldwide. Available in different specifications, these are offered at industry leading prices. If you need customized compressor housing in cast iron, gray iron, ductile iron, which produced by lost foam casting process, sand casting process, please feel free to contact gina@guokuncasting.com to get the quotation.