ASTM A48 Cast Iron Motor Housing

Part Name: Motor shell, motor housing, motor casing

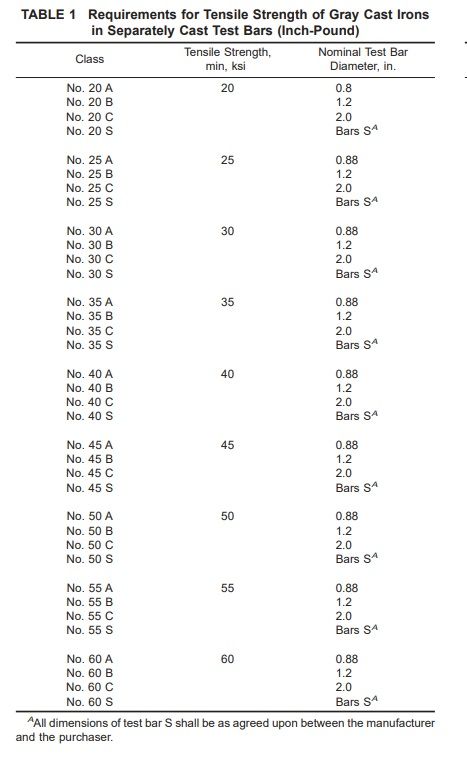

Metal: Gray cast iron ASTM A48 Class 35 or HT250

Metal casting: Lost foam casting and precision machining

Baoding Guokun is a professional motor castings factory of motor shell, motor housing, and motor casing with tight tolerance, no leakage and wear-resistance in grey cast iron and aluminum alloys ASTM A356. Please mail your inquiry to gina@guokuncasting.com to get a quotation.