Aluminum electric motor cover plate

Part Name: Motor castings, motor end cover

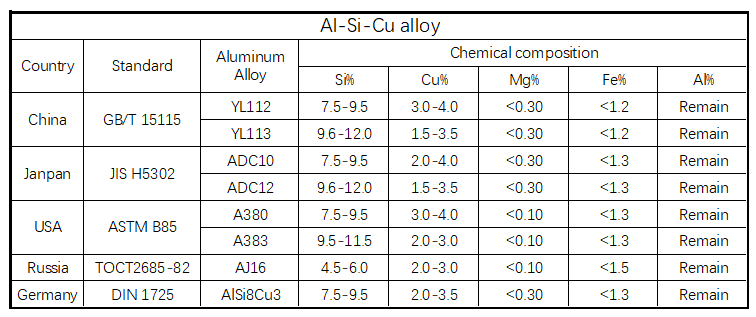

Metal: Cast steel, cast iron, aluminum alloy motor castings, ASTM A 356, ASTM A216, ASTM A48, ADC12, etc.

Process: Lost foam casting, sand casting or investment casting process and machining

Baoding Guokun can produce motor casting and engine casting parts, motor shell, end bracket, frame, cooling fan, end bracket, bearing housing and other custom motor casting as per your drawings. Please contact gina@guokuncasting.com to get a quote.