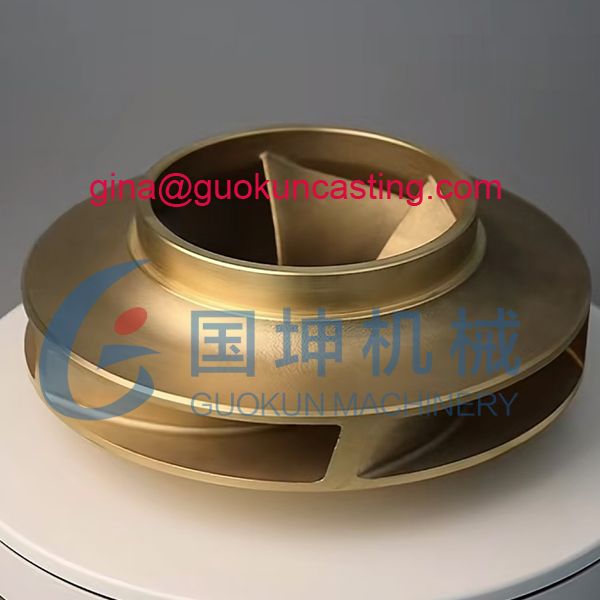

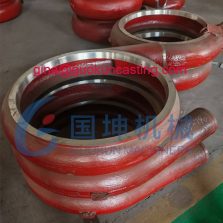

Aluminum bronze casting components for pumps

Baoding Guokun is located in Baoding city, Hebei province, China. Our sand casting factory occupies a total area of 30,000 square meters, which have casting foundry workshop, grinding, sandblasting and precision machining shop, laboratory and warehouse. Baoding Guokun has equipped with 4 sets medium-frequency electric furnaces, 15 sets automatic shell core machinery, automatic sand casting molding line, 7 sets CNC machinery, 20 sets CNC Lathe, and the complete quality inspection devices for mechanical testing and chemical analysis, including tensile strength, hardness tester, metallographic inspection, spectrometer, ultrasonic testing and special testing devices. Before shipping, the quality reports for all inspection will be issued and mailed to our customers. Please mail your inquiry to gina@guokuncasting.com